| |||||||||||

|

|

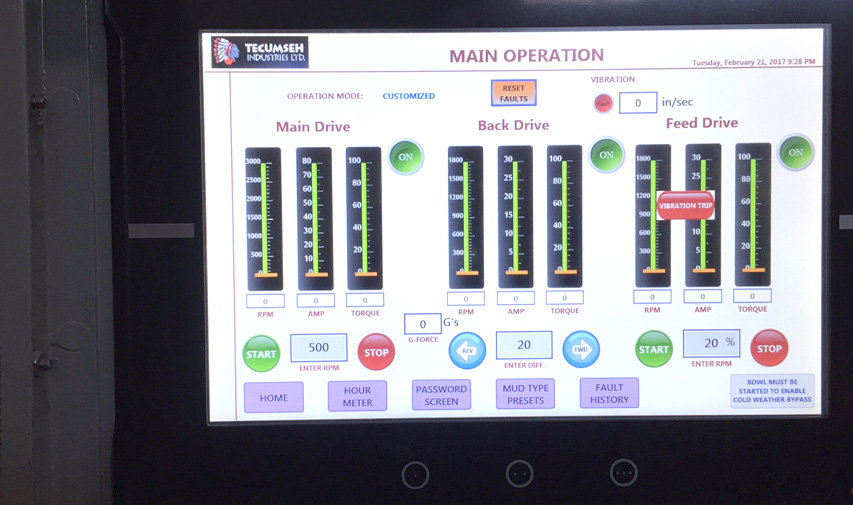

HOME > CUSTOM MANUFACTURING CENTRIFUGE CONTROL SYSTEMS Our state of the art Variable Frequency Drive (VFD) centrifuge control systems give operators total control over processing parameters while the centrifuge is in motion. Our control system consists of three individual VFD's mounted either in a portable enclosure (available with touch screens or simple switch gear) or in a Motor Control Center (MCC) building, depending on the application. Each VFD displays the motor RPM, current, and torque. The 3 VFD's operate the 3 main components of a centrifuge system (main rotating assembly, back drive, and feed pump) respectively. This flexibility allows for optimum performance and efficiently at all times. Not all slurries are of the same consistency so having the ability to fine tune the centrifuge allows for the best performance over a wide range of applications. Our control systems can also be programmed to adjust the feed rate as well as the differential speed in the event that the conveyor torque reaches undesirable levels. This greatly reduces centrifuge plugging. All control systems are available with a PLC and a touch screen HMI (human interface) if desired. Tecumseh centrifuge control systems are extremely user friendly and can be custom designed and programmed for specific application needs. With the touch of a screen, operators can set and adjust the centrifuge operating parameters to fit different process characteristics. A Pro Logic Control (PLC) and touch screen can also be added to the control system providing a level of control logic to help achieve your process automation and preset parameter needs.

| |||||||||

|

| |||||||||||

| ||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||