| |||||||||||

|

|

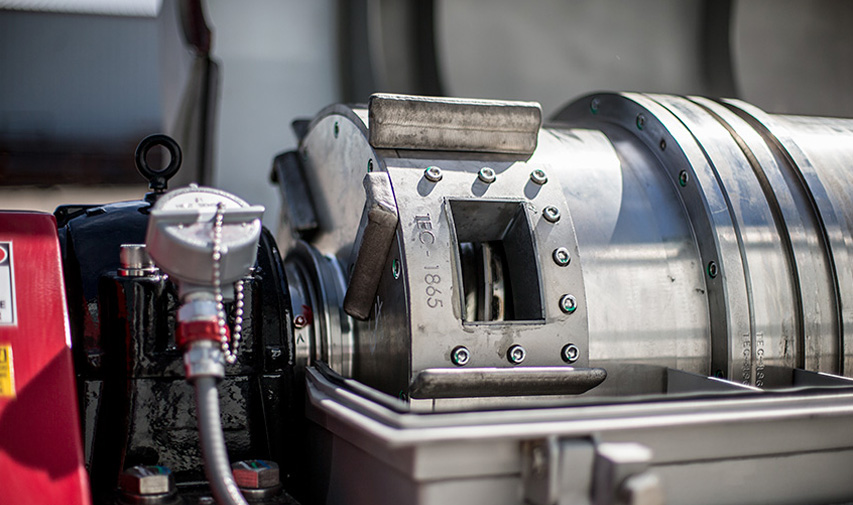

HOME > CENTRIFUGE MODELS TEC-1865 FULL VARIABLE SPEED CENTRIFUGE The TEC-1865-FVS centrifuge is a Full Variable Speed model, which provides operators with the ability to adjust operating parameters including the differential speed, bowl speed, and feed rates while the centrifuge is in operation. Our 1865 Full Variable Speed centrifuge has the added benefit of a "direct drive" Conveyor drive assembly. With this new conveyor drive design, we have increased the efficiency of the conveyor drive motor significantly as well as eliminated any maintenance issues associated with utilizing belts and sheaves. A Pro Logic Control (PLC) and touch screen can also be added to the control system providing a level of control logic to help achieve your process automation and preset parameter needs. Flexibility, reliability and performance are attributes that all of our centrifuges come with. Tecumseh, we truly are the experts!

BUILD NOTES -6 Solid Discharge Ports -6 Liquid Discharge Ports -Seals are Viton/Buna-N -Stainless Steel Construction -Wear Protection -Tungsten Carbide -Removable Liner in Bowl Section OPERATING SPEEDS FOR OILFIELD APPLICATIONS BOWL SPEED: 800 - 1,800 RPM ACCELERATION: 163 - 830 G's DIFFERENTIAL: 30 - 60 RPM BOWL SPEED: 1,900 - 3,150 RPM ACCELERATION: 922 - 2,536 G's DIFFERENTIAL: 10 - 30 RPM BOWL SPEED: 3,150 RPM ACCELERATION: @ 3,150 RPM: 2,536 G's DIFFERENTIAL: 10 - 60 RPM OTHER SPECIFICATIONS BOWL DIMENSIONS: 18in x 65in (457.2mm x 1651mm) BEACH ANGLE: 10-degree beach angle POOL PORT (POND) ADJUSTMENT: 1 - 13 units of adjustment MAIN DRIVE MOTOR: 125hp CONVEYOR DRIVE MOTOR: 25hp WEIGHT (EMPTY): 12,500lbs (5,670kgs) FLIGHTING PITCH: 146mm (5.74in) MAXIMUM SAFE OPERATING CONVEYOR TORQUE: 80,000 in/lbs (9 kNn) of torque GEARBOX RATIO: 56:1 ratio POWER REQUIRED: 2 - 100 amp plug @ 480 VAC 'G' FORCE CALCULATION *The following is a formula used to calculate 'G' force: G = Bowl Diameter (in) X Bowl RPM2 X .0000142  | |||||||||

|

| |||||||||||

| ||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||